Project

The Great Astronomical Clock 2011-2015

Original, unique design. Precise, meticulous workmanship. Many years of patient, consistent, titanic work. A perfect combination of timeless classics and modern solutions, surprising with its possibilities.

Astronomical

10 years of work

The creation of the Great Astronomical Clock took 10 years, including the assembly which took 5 years in itself. The project was finally completed in 2015.

An absolutely extraordinary astronomical clock.

The Great Astronomical Clock 2011-2015 is a demonstration of the perfect synergy between tradition and modernity.

It is a coherent, precise and effective combination of multiple mechanisms. Thank to this combination, an astronomical clock has been attained that allows us to travel through time.

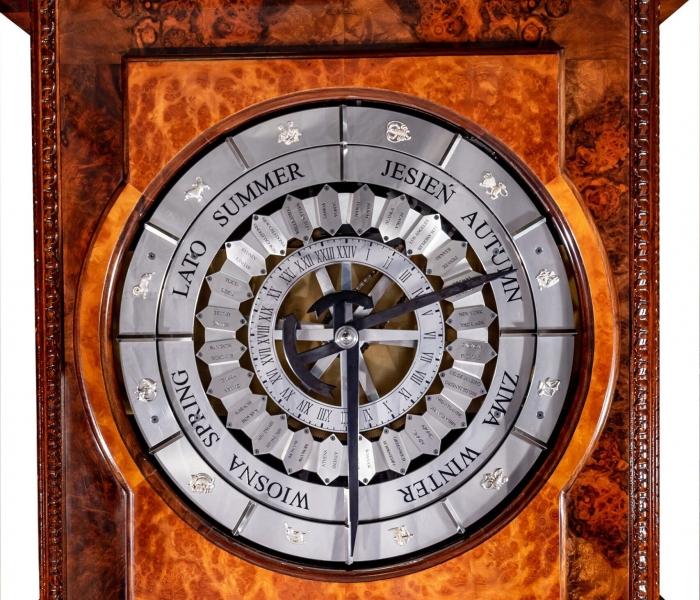

Functions

Functions/indications

The clock has the following functions/indications:

1. second hand

2. hour dial – 12 hours

3. hour dial – 24 hours

4. date indicator

5. days of the week

6. months

7. years

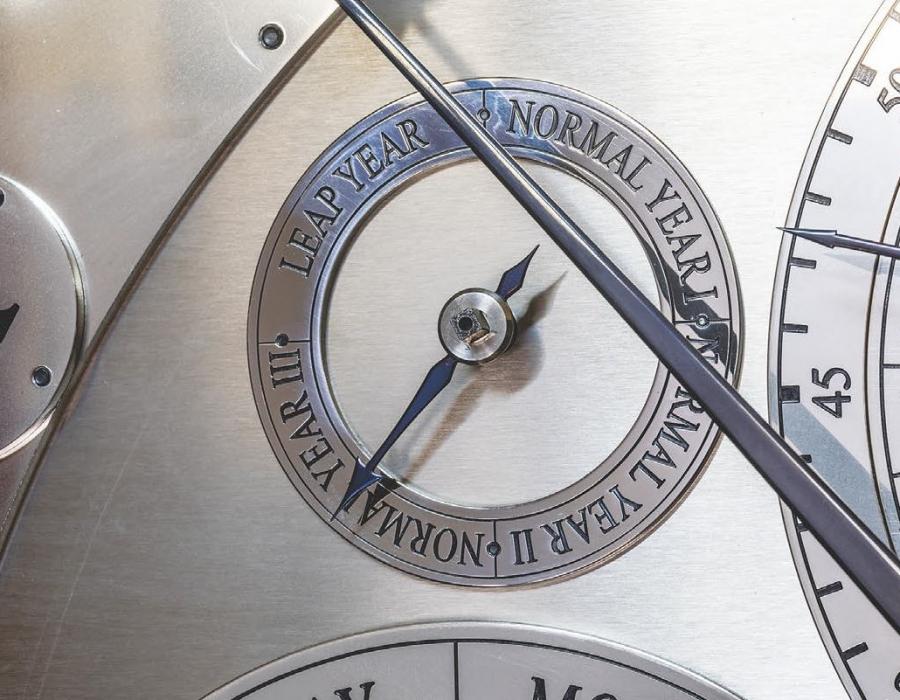

8. ordinary/leap years

9. declination of the sun

10. sunrise

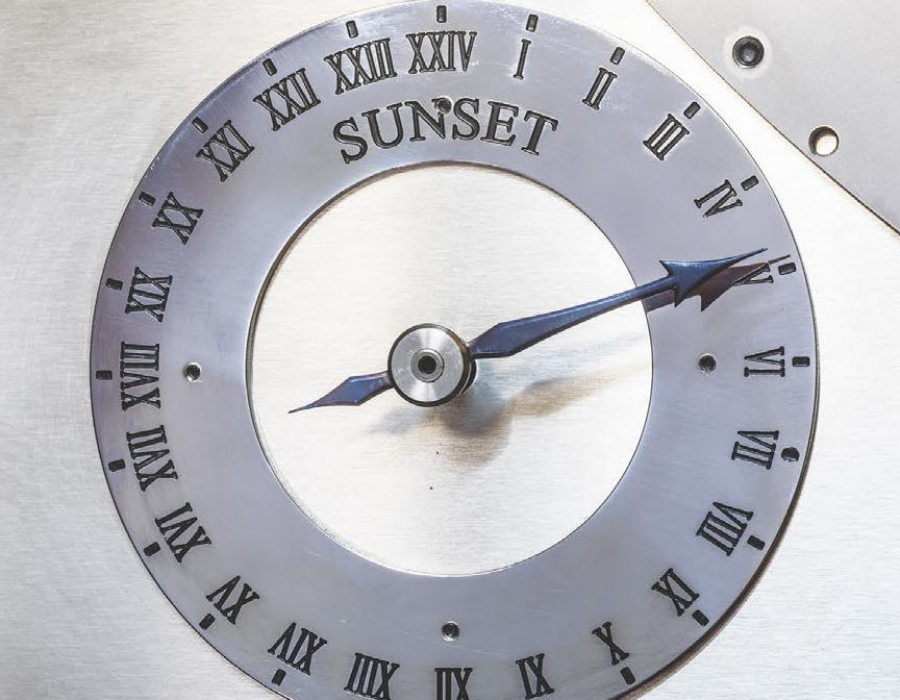

11. sunset

12. phases of the moon

13. time zones

14. seasons

15. zodiac signs

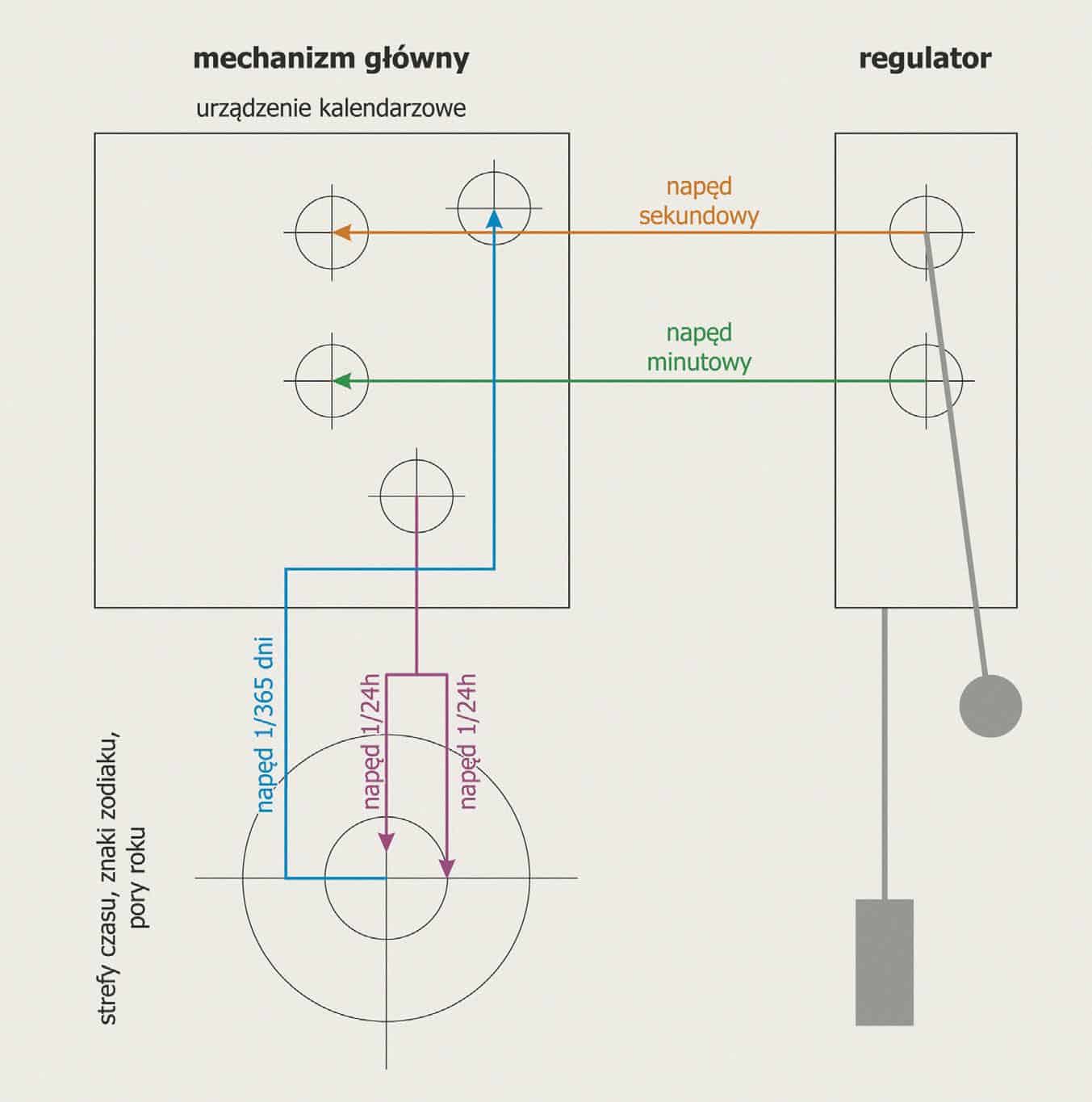

Diagram

Diagram

of operation

MECHANISMS

Basic mechanisms and parts

- drive –

regulator

- annual gear

mechanism

- clock case

(base, display case)

- "transmission"

mechanisms

- Mechanism

of the tensioning

- highly complex

main mechanism

DESCRIPTION OF OPERATION

Description of operation

The clock drive (regulator) drives the seconds hand axis and the minute hand axis of the main mechanism. The main mechanism controls the movement of the hands visible on the main dial, in addition to the "sunrise", "sunset" and "sun declination" hands. It also controls the year indications in the four fields of the main dial.

The main mechanism acts as a complete calendar device. It does not have automatic date correction. The main mechanism drives the annual gear, via the transmission mechanism, at a speed of 1 revolution/24 hours, and the 'time zone' indication dial at the same speed.

The annual gear axis makes 1 revolution in 365 days. A speed of 1/365 days has been achieved by using a worm gear. The annual gear, in addition to the "season" and "zodiac signs” indication drive, controls the "sunrise", "sunset" and "sun declination" indications on the main dial via the transmission mechanism. If necessary, the date should be adjusted with the key from the toolkit provided with the clock. Once every four years, the clock should be stopped for 24 hours to maintain the correct indications of 'sunrise', 'sunset', 'sun declination', 'zodiac signs' and 'seasons'.

Interruptions in the operation of the timer result in the erroneous setting of the aforementioned functions and make it necessary to correct the setting.

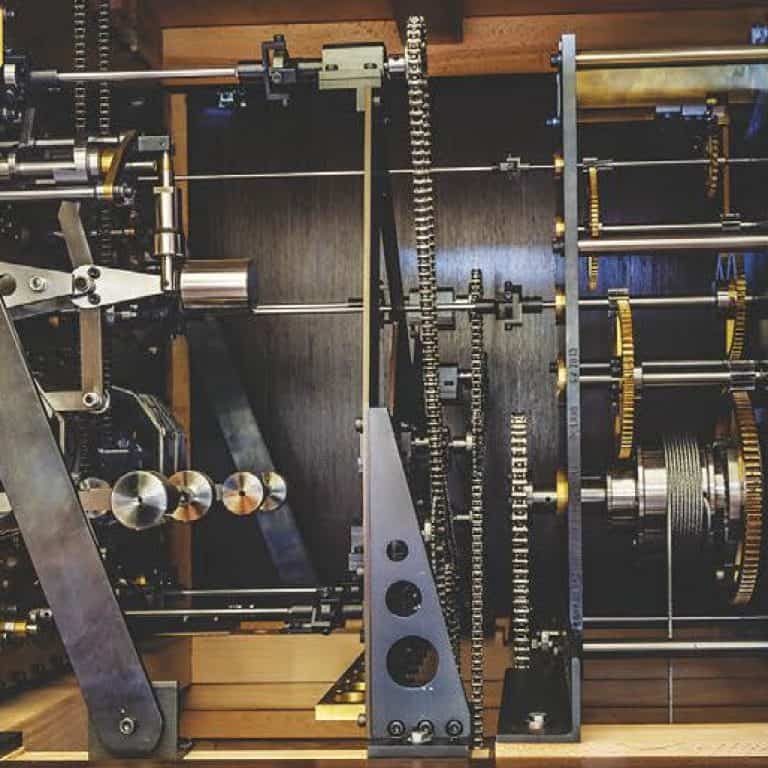

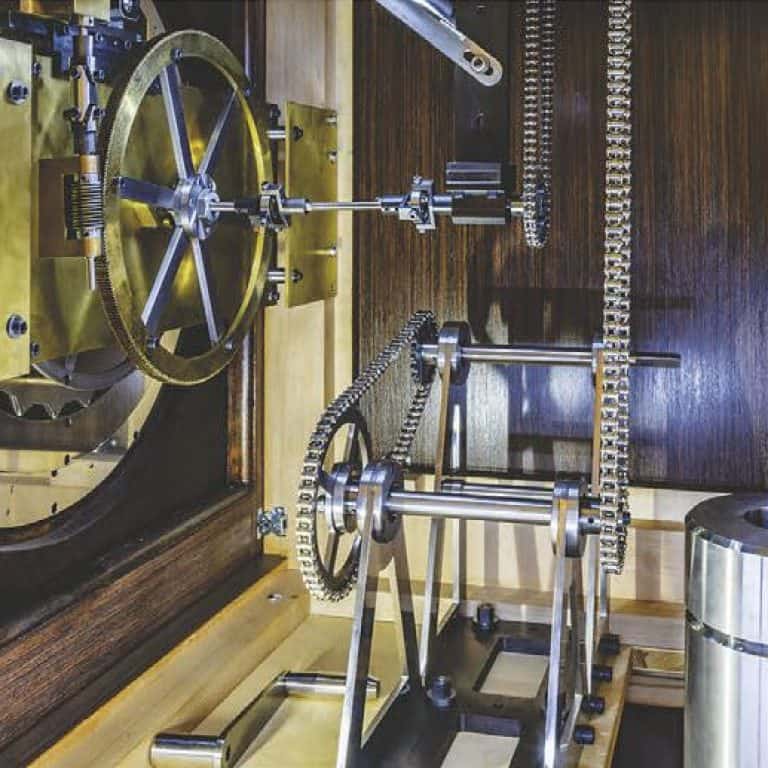

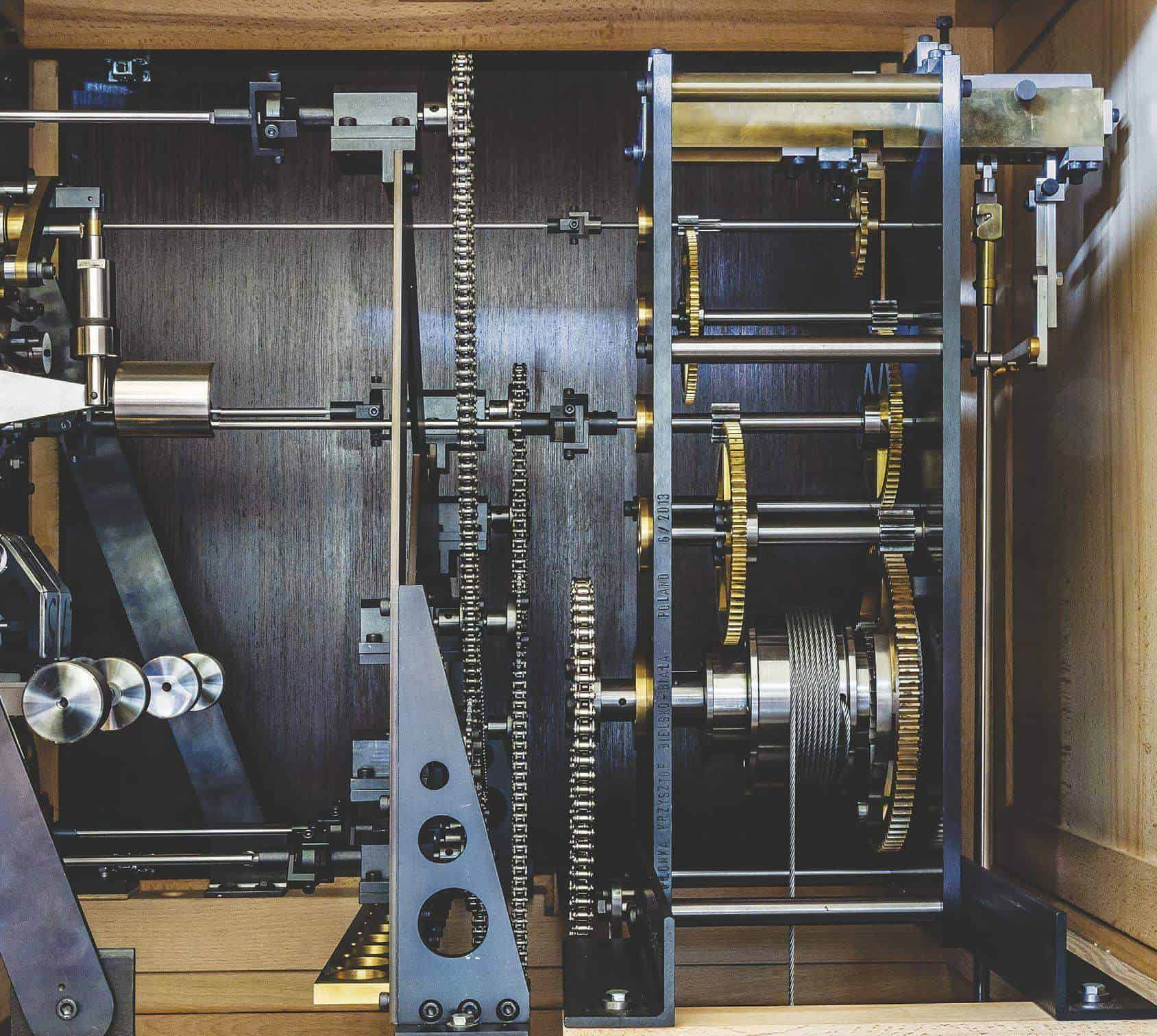

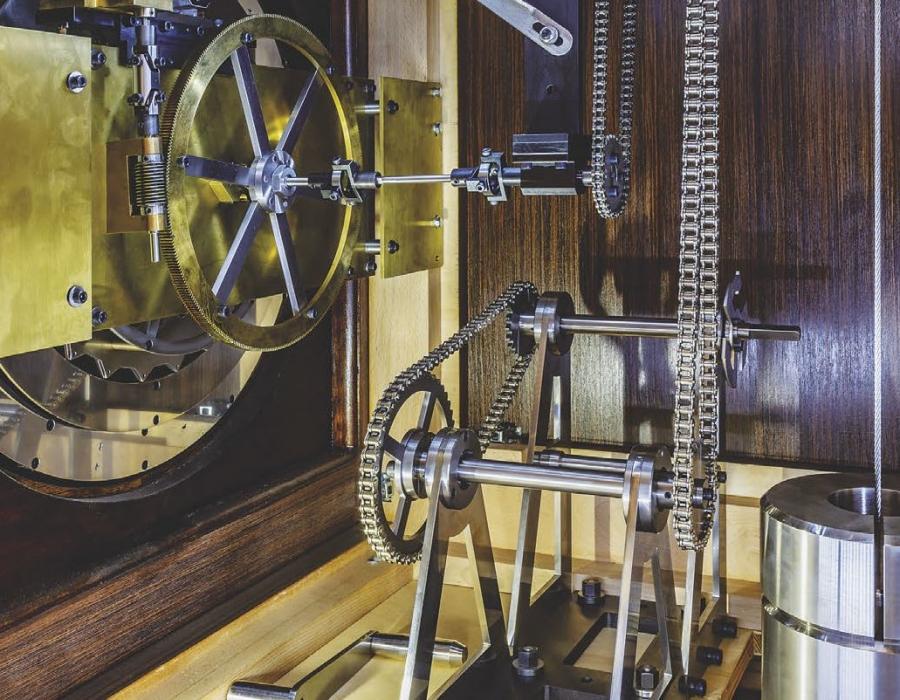

DRIVE MECHANISMS

Drive mechanism (regulator)

The clock mechanism is a modern design the size of a small tower clock. Ball bearings have been used for all axes of the mechanism due to the need to increase the durability of the mechanism and reduce rolling resistance. The pendulum and anchor have been fitted with two knife supports resting on the prism sockets of the mechanism. The anchor-pendulum connection has been equipped with a pendulum swing regulator and a safety device to protect the capture wheel and the pallets from damage in the event of a pulse failure. The seconds pendulum has thermal compensation. The mechanism has a cable tension, with a power reserve of approximately 5 days.

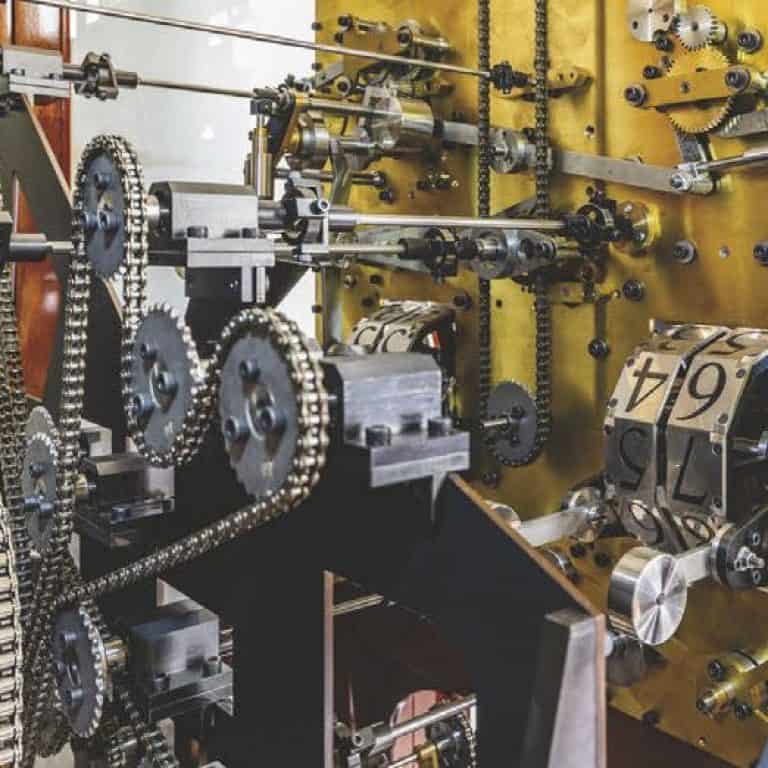

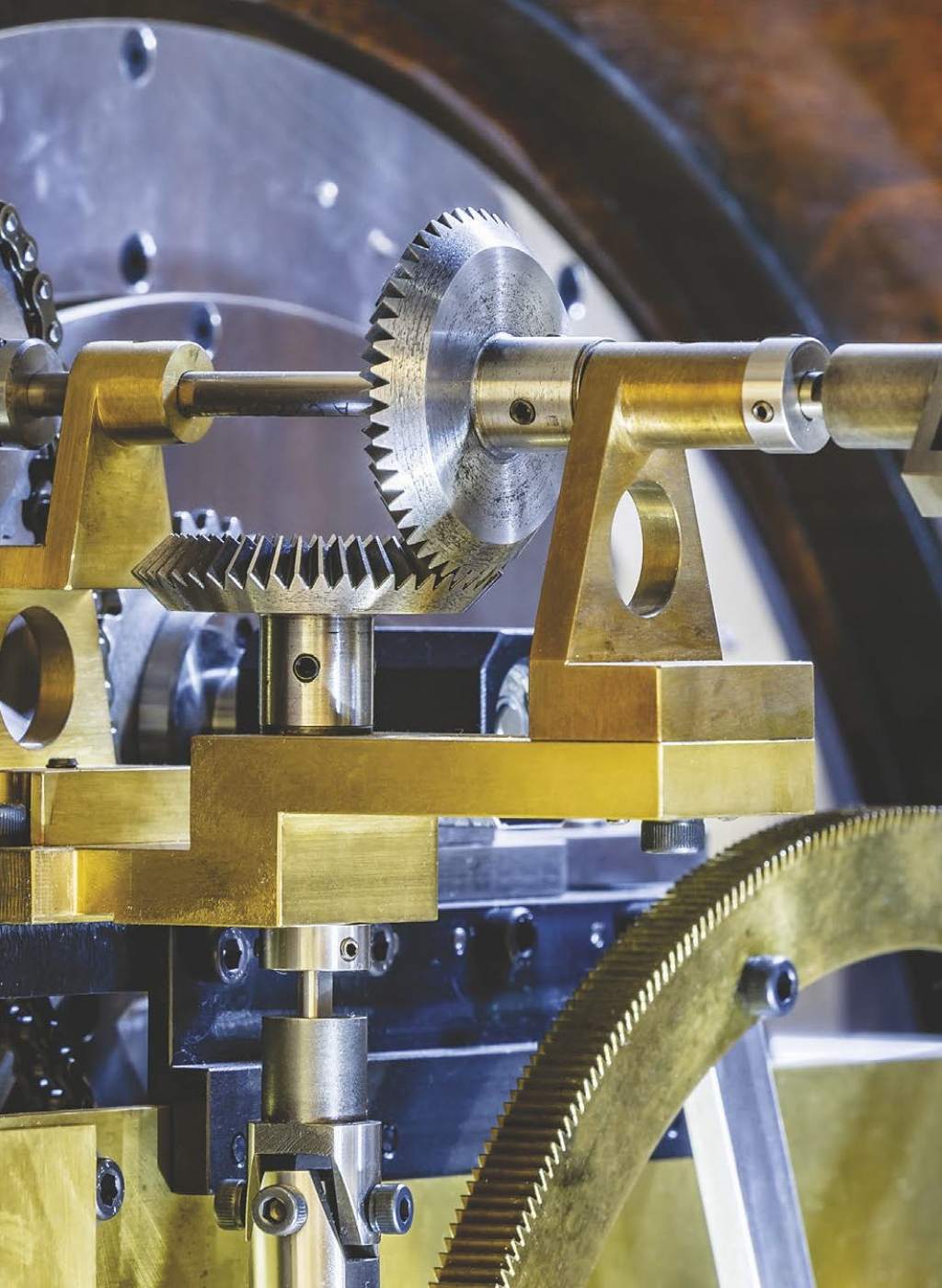

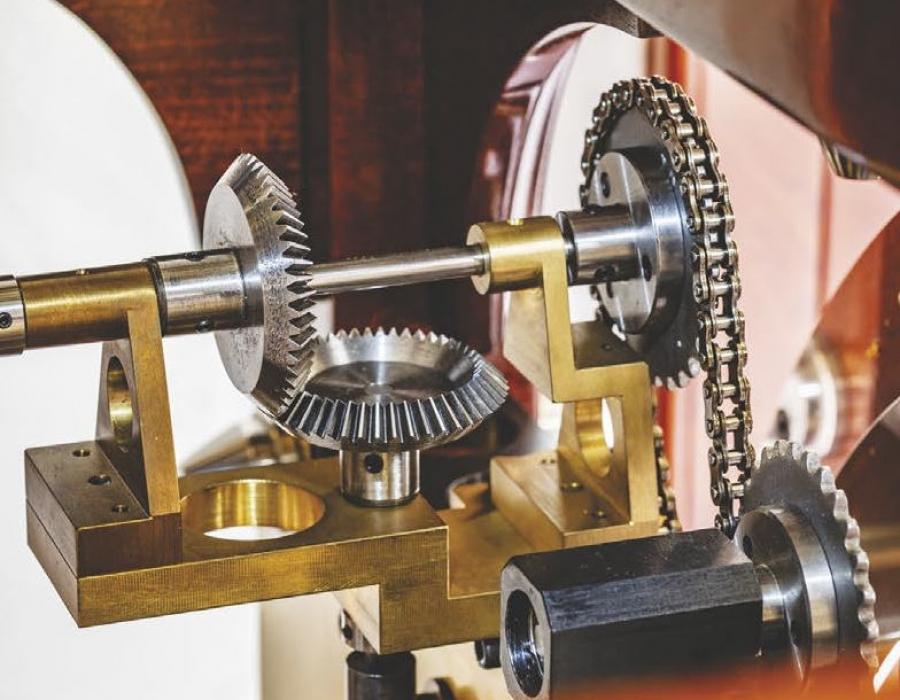

TRANSMISSION MECHANISM

Transmission mechanism

The transmission mechanism, located between the drive (regulator) and the main mechanism, distributes the drive in multiple directions and planes via sprockets, Gall chains, and drive axles. Bodies with roller-bearing-mounted sprocket axles have been fixed on the mechanism plate. Each sprocket system has adjustable chain tension, and the drive axles are fitted with longitudinally sliding Cardan joints to protect the entire linkage system from additional rolling resistance. All structural components of the drive mechanism involved in the clock's operation have been heat-treated to increase the durability of the components.

TENSIONING MECHANISM

Tensioning mechanism

In order to wind up the clock, a crank is applied to the quadrant of the winding axis. The axis of the tensioning mechanism is mounted to the wooden clock case by means of two brackets. An additional pair of sprockets makes it possible to reduce the force required to wind the clock up. The sprocket axles are housed in bodies fitted with ball bearings. By means of a Gall chain and a sprocket integrated into the axle of the clock drive mechanism's cable reel, wind the clock by turning the crank in the direction indicated by the arrows.

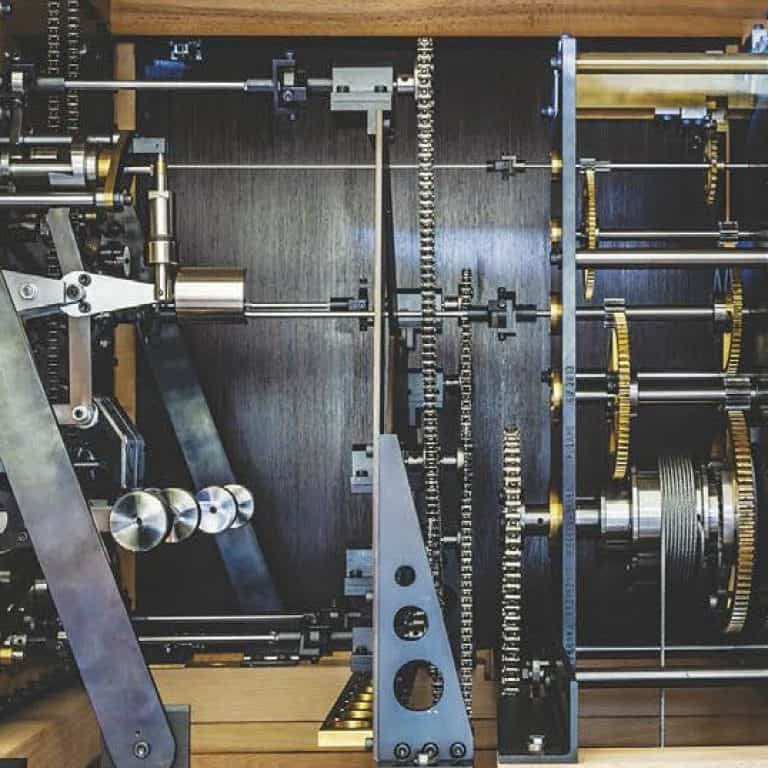

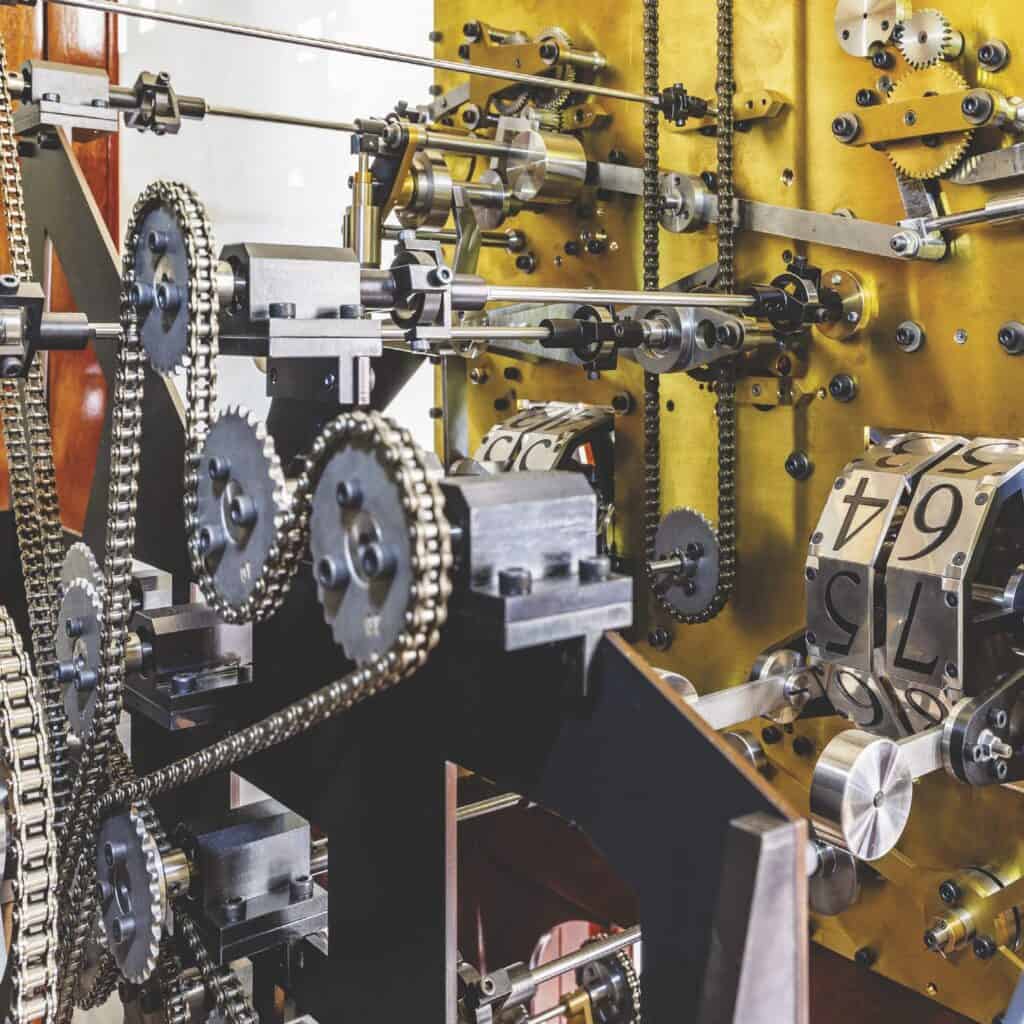

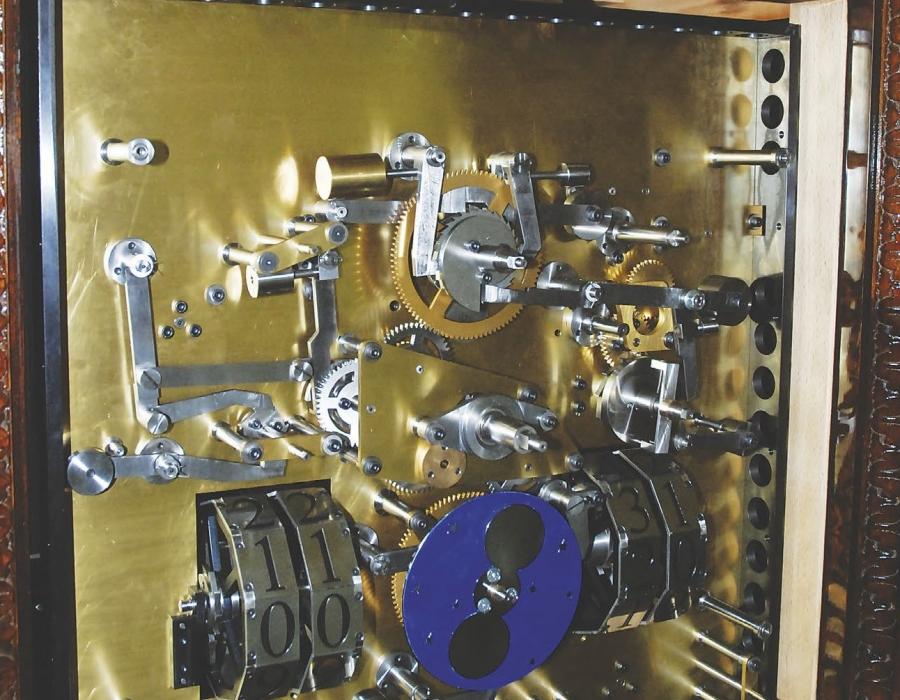

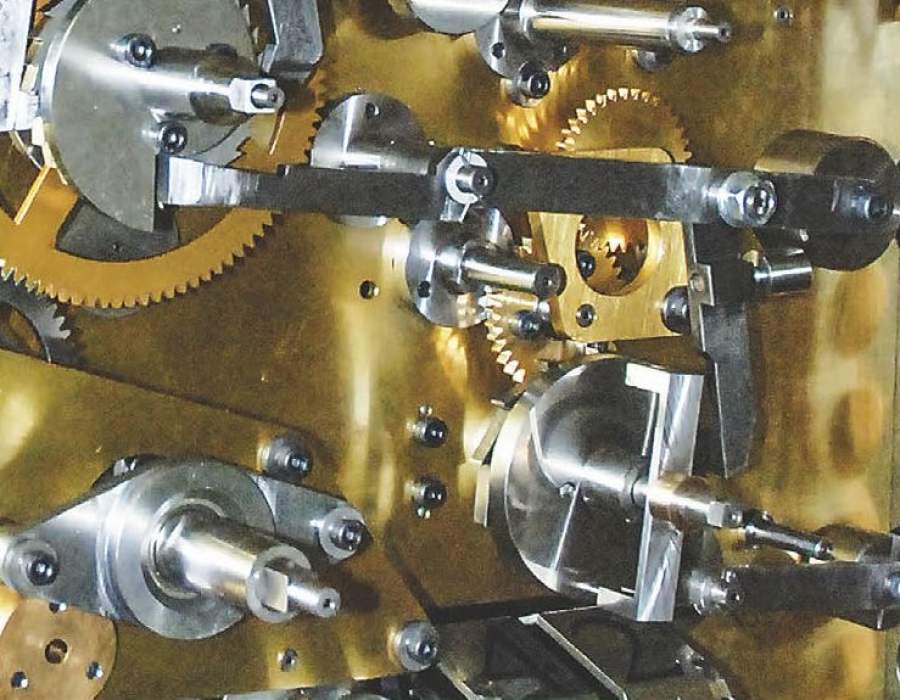

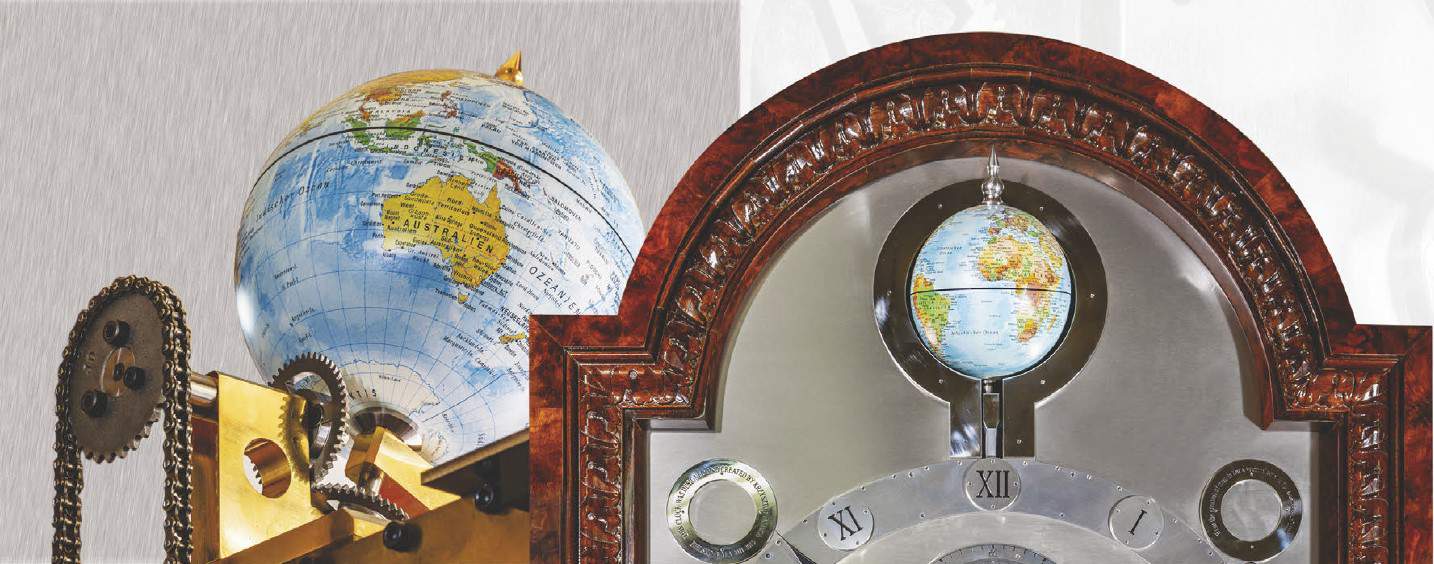

Main mechanism

MAIN MECHANISM

The main mechanism of Krzysztof Płonka's astronomical clock is a highly complex calendar device that controls all the clock's functions.

The central axis of the main mechanism makes 1 revolution per hour – this is the minute axis. Through gears with a gear ratio of 1 revolution/24 hour, the drive of the date display, days of the week, moon phase, GMT time indications – (24-hour dial), globe drive, time zone drive, and worm annual gear drive have been obtained. A gear system with a ratio of 1 revolution/12 hours drives the hour hand.

At the top of the main mechanism is the second hand axis which has been integrated with the date axis. The date change is implemented using a cam, an impulse lever and a 31-tooth wheel.

Changing the date to the first day of the month changes the name of the month on the dial on the right-hand side of the mechanism. Depending on the number of days in a given month, the date indication must be adjusted.

The 24-hour dial, integrated with the moon phase mechanism, is visible at the bottom of the mechanism. The indication of the moon phases is carried out by means of a cam, an impulse lever, and a 59-tooth wheel.

The main mechanism drives the rotation of the globe via a gear and Gall chain.

A dial with the names of the days of the week is located on the left side of the main mechanism. Changing the settings is carried out using a ratchet wheel, an impulse lever, and a 7-tooth wheel.

The year indication mechanism located in the four fields of the dial consists of four rotating drums with the numerals 0 to 9. The mechanism automatically changes the year when the month name is changed to January. The mechanical counter changes the display automatically for 99 years. After this period, the settings in the fields on the left-hand side of the dial should be adjusted manually. Each time the year changes, the setting of the indicator on the dial changes – "ordinary years – leap year".

The main mechanism drives the annual gearbox at a rate of 1 revolution/365 days. The drive works by means of gear wheels of the main mechanism, chain gears of the drive transmission mechanism and a worm gear. The annual gearbox is responsible for the indications – 'seasons', 'zodiac signs', 'sunrise', 'sunset', and 'sun declination'. The above indications have been obtained with gears, levers, and cams making one revolution in 365 days. The system needs to be revised every 4 years.

To the left of the date dial is a dial indicating an ordinary or a leap year. The mechanism controls the hands axis using cams, levers, an impulse lever, and a wheel with 8 teeth. The change in indication occurs as the year indication changes.

The 'sunrise', 'sunset', and 'sun declination' indications visible on the clock's main dial are driven by an annual gear axis, located at the bottom of the clock, via sprockets, Gall chains, and a cam system. Thanks to this mechanism, information concerning what time the sun rises and sets depending on the season is provided. The "sun declination" dial informs us about the daily proportion of day and night hours.

Clock housing

The clock housing has been handcrafted from hardwood, all finished in walnut wood and varnished.

Clock housing

Equipment

The clock is equipped with a box containing a set of tools that may be needed during operation. The equipment includes a crank for winding the clock up, special keys for setting the hands, a universal puller for pulling off the hands and Allen keys.

The tools are housed in a designed and handcrafted box finished in walnut wood.

Equipment

Rules

Rules for using the clock

Due to its size and weight, the clock must be partially disassembled for transport and then reassembled once in position. The room where the clock is located should be dry and at the right temperature. The clock must not be exposed to shocks. Comprehensive information on the construction and rules of use is provided by the clock maker.

Basic operating principles:

01

The clock is to be wound up using the crank provided. Systematically check the condition of the weight cable.

02

Only adjust the display using the keys provided.

03

Do not reverse the hands of the clock – you risk damaging the mechanism.

04

If the clock is disturbed, under no circumstances should the mechanism be tampered with. Any faults can only be rectified by a professional.

05

Periodically – every 4 to 5 years – the clock mechanisms should be maintained and lubricated.

Observing these rules ensures the correct operation of the clock for many years.

- Technical data: height – 260cm, width – 100cm, depth – 95cm, weight – approx. 360kg

Krzysztof Płonka

Krzysztof Płonka

He was born in 1952 in Ślemień near Żywiec, where he lived and attended primary school. In 1966, he began studying mechanical engineering, machining and precision mechanics in Bielsko-Biała. He has been self-employed since 1990. Since the beginning of his career, clock constructions have become his lifelong passion.

It deepens the knowledge of the history and construction of mechanical clocks, and at the same time rebuilds unique, antique clocks, restoring them to all functions, which allows them to operate.

In 2005, he obtained a patent for the "Chronometer Clock Grab" No. 204808, which he designed.

During this time, he begins building astronomical clocks of very high complication and "Regulator" type standing clocks.

Currently, he is working on the implementation of Krzysztof Płonka's "Great Astronomical, Figural Tower Clock" and rescues old, antique mechanical clocks from total oblivion by restoring their utility functions.