Project

Floor clock REGULATOR 2018 No. 2

This majestic Regulator is much more than an extraordinary design. It is at the same time a masterpiece of watchmaking art.

Carefully thought out and planned design. Precise, patient, sophisticated workmanship.

DESCRIPTION OF OPERATION

Parameter

Floor clock with a regulator dial signed "Krzysztof Płonka 2018 Nr 1 Bielsko-Biała Poland"

It is a one-off, in-house construction. Both the mechanisms and the housing have been designed

and made from scratch. The base of the clock and the case of the mechanism are made of lacquered wood. The clock columns, weight, adjustment feet and other components are made of high-quality stainless steel.

height of the clock – 270 cm

base depth – 60 cm

base width – 90 cm

weight of the clock – 150 kg

DIAL

Dial made of stainless steel, precise print protected with a layer of clear varnish.

Hour, minute and second hands.

At the bottom of the clock face, a hole for the crank.

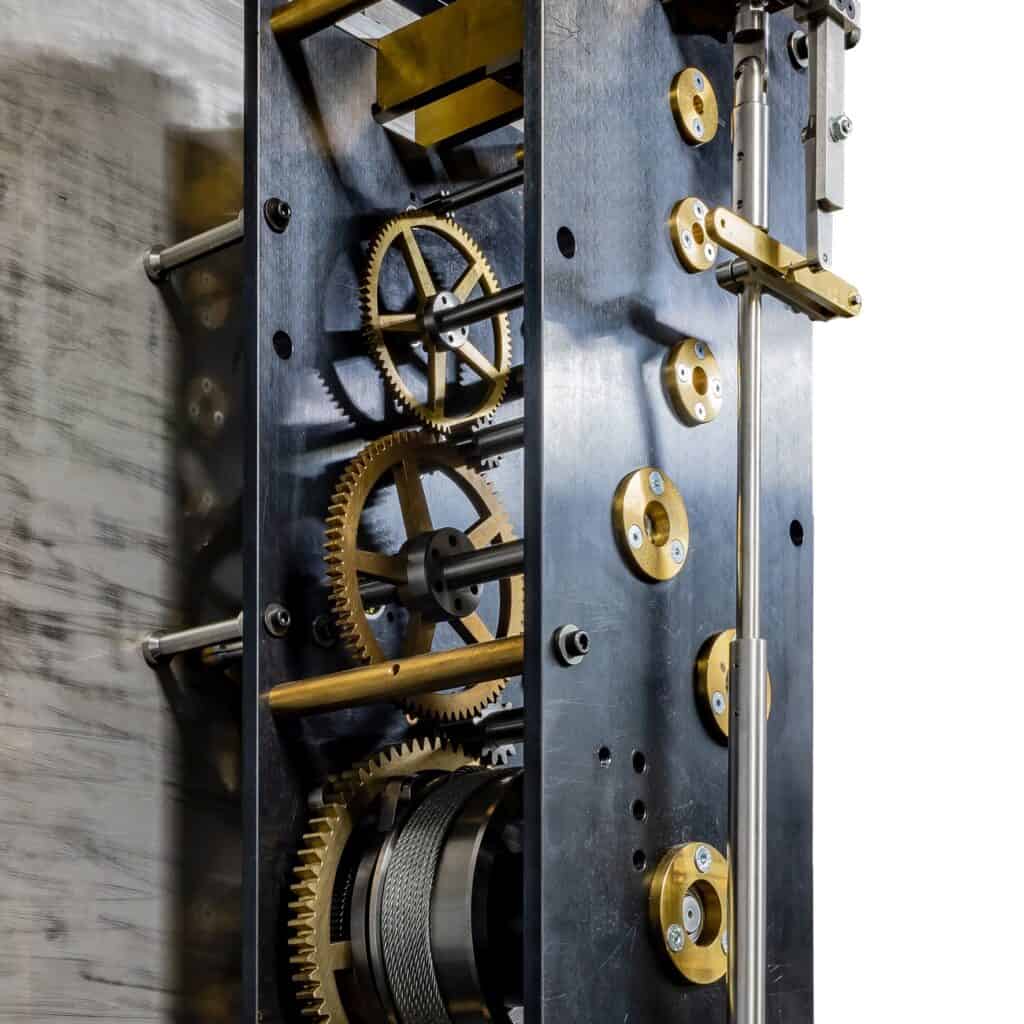

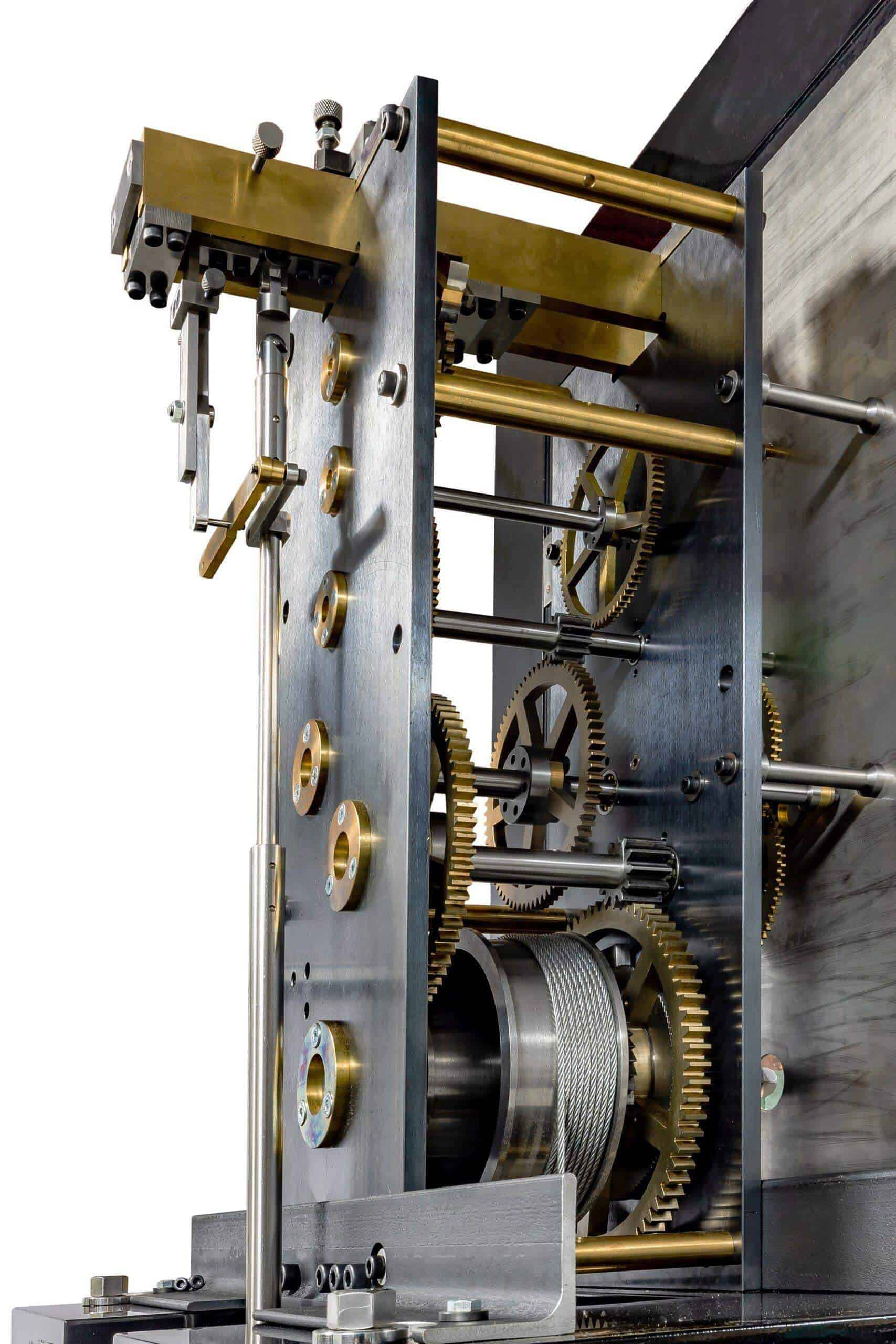

CLOCK MECHANISM

Mechanism

The clock mechanism is a modern design the size of a small tower clock. Ball bearings have been used for all axes of the mechanism due to the need to increase the durability of the mechanism and reduce rolling resistance. The pendulum and anchor have been fitted with two knife supports resting on the prism sockets of the mechanism.

The anchor-pendulum connection is equipped with a pendulum swing regulator and a safety device to protect the capture wheel and the pallets from damage in the event of a pulse failure. Cable tension, 30-day operation, the seconds pendulum has thermal compensation.

PENDULUM

Pendulum

The seconds pendulum mounted on knife supports. Made of high-quality stainless steel, equipped with precise adjustment.

The pendulum has thermal compensation, which allows for the high precision of the clock.

Operation

Operation

While the clock is in use, it should be protected from knocks so as to ensure the mechanism does not become damaged.

If transport is required, the mechanisms must be dismantled and the catch secured with suitable screws.

When winding the clock up, pay attention to the condition of the weight cable. The crank is an accessory of the clock.

The hands can be set by loosening the nut of the central minute axis.

Once the correct time has been set, lightly tighten the nut.

Lubricate of the mechanism every 4-5 years, the ball bearings do not require lubrication.

Proper operation ensures the operation of the clock for many years.

Krzysztof Płonka

Krzysztof Płonka

He was born in 1952 in Ślemień near Żywiec, where he lived and attended primary school. In 1966, he began studying mechanical engineering, machining and precision mechanics in Bielsko-Biała. He has been self-employed since 1990. Since the beginning of his career, clock constructions have become his lifelong passion.

It deepens the knowledge of the history and construction of mechanical clocks, and at the same time rebuilds unique, antique clocks, restoring them to all functions, which allows them to operate.

In 2005, he obtained a patent for the "Chronometer Clock Grab" No. 204808, which he designed.

During this time, he begins building astronomical clocks of very high complication and "Regulator" type standing clocks.

Currently, he is working on the implementation of Krzysztof Płonka's "Great Astronomical, Figural Tower Clock" and rescues old, antique mechanical clocks from total oblivion by restoring their utility functions.